We have a 600 years history in shipbuilding

Murat Kıran, Chairman of the Shipbuilders' Association, states that the innovative and competitive structure of the Turkish shipbuilding industry is remarkable for the whole world.

Murat Kıran, Chairman of the Shipbuilders' Association, states that the innovative and competitive structure of the Turkish shipbuilding industry is remarkable for the whole world. Drawing attention to the increasing capability of the sector in the field of new shipbuilding, Kıran said, “due to the changing and developing market conditions, we have turned to innovative and high value-added projects since the 2010s. As of today, we have completed and delivered hybrid, fully electric, and environment-friendly projects, many of which are the first of their class in the world, in this market. We can proudly say that we are in the 4th place in the world in yacht and mega-yacht building and that we continue to be among the top 5 as in previous years.” Kıran proudly talks about the bright future of the industry. We talked with him about the shipbuilding industry in general, and the possible effects of the Russia-Ukraine war on the sector.

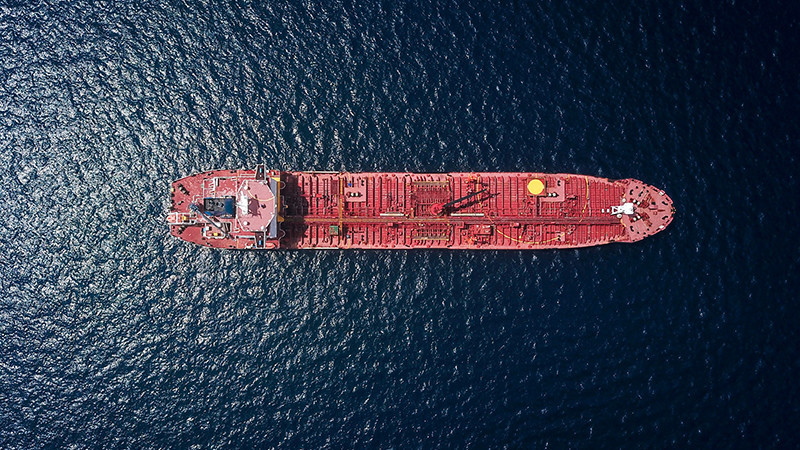

Evaluating the volume, strengths, and advantages of the Turkish shipbuilding industry, Murat Kıran said, “there is no doubt that our Turkish shipbuilding industry has a prominent position in our region and all over the world. Indeed, the fact that we have 84 active shipyards in our country and 33 floating docks and 11 dry docks in these shipyards, and 44 docks in total is a serious indicator of our strength. It should be noted that the total length of these pools is 7 thousand 993 meters.

Kıran continued his words as follows: "The fact that our new shipbuilding figure exceeded 1 billion 630 million dollars in 2021, excluding maintenance-repair and military ships, is our biggest source of pride in this regard. We know our strengths and advantages well. We are trying to turn them into leverage. The Turkish shipbuilding industry, which has a long history of more than 600 years, is getting stronger day by day by adding its world-renown in small-tonnage ships and brand perception of small chemical tankers, and tugboats, fishing vessels, mega yachts to its shipbuilding experience gained over many years. We are in a strategically important industrial position, which is known in the world and continues its successful activities, in particular, in terms of our ability to build military ships, professional competence in the detail design stage, the availability of shipowners supporting the shipbuilding industry, material quality, proximity and recognition to the European continent in ship maintenance and repair, the development of the subcontractor expertise system, and the ability to create a significant amount of employment considering the experience of the past years.”

“We are in the 7th place in the world on the basis of quantity”

Explaining the sector's position in the world shipbuilding field, the types of ships it produces, and its capabilities in the field of repair and maintenance, Kıran said: “In the global new shipbuilding order book, Turkey ranks seventh in terms of quantity and fourteenth in terms of tonnage. These numbers are an indication of how well-positioned we are. Our goal is to bring our industry to a better place. We are taking very consistent and big steps in this regard. You may see how well we are on the right track and doing remarkable work when you look at the projects such as the world's first battery-powered all-electric tugboat, the world's largest live fish transport vessel, the world's first remote-controlled tugboat, the world's first LNG-powered tugboat, the world's largest electric ferry in its class, the world's first battery- and LNG-powered fishing vessel, the first energy conversion vessels, and the largest sailing yacht.

“We are a maintenance-repair base”

"With our annual maximum ship maintenance-repair capacity of 25 million DWT, we are considered Europe's maintenance and repair base as everyone's consensus. When we look at the industry in general, especially when we consider the negative impact of COVID-19, We can say that we are in a strong position. In addition to our volume in ship and yacht production, our key position in the global market comes to the fore when our maintenance and repair activities and military ship projects are added. We can easily say that we have become the world's most experienced small-scale chemical tanker manufacturer in about 10 years. Due to the changing and developing market conditions, we have turned to innovative and high-value-added projects since the 2010s. As of today, we have completed and delivered hybrid, fully electric, and environment-friendly projects, many of which are the first of their class in the world, in this market. We can proudly say that we are in the 4th place in the world in yacht and mega-yacht building and that we continue to be among the top 5 as in previous years. In special-purpose projects, our ability to meet customer demands, our deadlines, and our quality of workmanship enables us to be preferred and strengthen our position.”

Explaining the annual capacity, employment rate, and volume of domestic and international orders in the Turkish shipbuilding industry, Kıran said, “Our shipyards continue to build off-shore auxiliary vessels, fishing/transport/factory vessels, Ro-Ro vessels, tugboats, and coasters mainly for export. In addition, it continues to build military ships for our Navy. Our annual maximum steel processing capacity is 700,000 tons, and our annual maximum new shipbuilding capacity is 4.65 million DWT. On the other hand, we can say that our total number of employees is at least 200,000 people, with at least 50,000 people being directly employed.”

EU projects in progress

Evaluating the "Safe Shipyards Project with Technology-Based Training" initiated with the cooperation of GISBIR and the European Union, Kıran said, “we are carrying out the 'Safe Shipyards with Technology-Based Trainings Project' in cooperation with the Turkish Shipbuilders' Association (GISBIR) and the European Union (EU). Within the scope of this project, an e-learning platform was established to provide occupational health and safety training to develop innovative, technology-based learning models such as virtual reality and e-learning for shipyards. Four shipyard-specific training modules (safe working at height, electrical safety, work permit (hot-cold working), load transfer, and safe circulation within the shipyard) are being developed. Two of them (safe working at height and electrical safety) have been completed. In addition, two shipyard-specific virtual reality modules have been developed, namely indoor working and working at height. To introduce the education management system and virtual reality modules, an information seminar was held at Piri Reis University on March 24, 2022. In addition to the students and teachers of Piri Reis Vocational and Technical Anatolian High School, Pendik Barbaros Hayrettin Paşa Vocational and Technical Anatolian High School, Tuzla Vocational Training Center, and Piri Reis University, there was also great participation from the shipyards.”

Future plans

Considering the changing and developing ship diversity in the world, Kıran talked about GİSBİR's medium and long-term plans in this field and continued: “We can say that a new maritime understanding has started with the changing world order and conditions. The ultimate goal of the UN international maritime organization IMO, of which our country is a member, is to reduce greenhouse gas emissions to zero by the end of this century. This target has been set out gradually as follows: To reduce the emissions of carbon, sulfur, and nitrogen gases, which are polluting and leaching into the air as a result of the combustion of fossil fuels, by at least 40% by 2030. To be reduced by at least 50% by 2050. And finally, to zero by the end of this century. EU countries, on the other hand, aim to reach the zero target by 2050. In the process leading to all these goals, there are conditions that the ships have to comply with gradually from design to operation, but for the final goal, of course, integrated solutions, alternative fuels, and/or energy sources must be put into use. Today, the focus is on zero-emission, battery-powered, hybrid, alternative fuel, and similar environmental technologies. Constantly changing and evolving rules pose serious challenges in new shipbuilding. Both ship owners and engineers have difficulties in applying new technologies. This both increases the costs in new shipbuilding and results in the complexity of designs and longer delivery times. When we take into account the impact of the economic conjuncture, it is clear that the recent acceleration of our Turkish shipbuilding industry, especially in the field of new shipbuilding, is even more valuable in terms of demonstrating our capabilities.”

The target is hybrid ships

“I would like to point out that our industry mainly exports battery-powered/hybrid, innovative ships that meet the green agreement targets to EU countries. While some countries in the world make shipbuilding subsidies, it is not easy to increase exports every year. However, thanks to our innovative projects and our work quality, we will be able to turn the competition in our favor. Within the scope of the green agreement, the need to turn to environmental technologies, which especially concern shipowners, requires an increase in financial resources and inevitably increases costs. We believe that the necessary renewals and transformations for ships will continue rapidly in the coming years as long as access to available technologies and financial resources are provided. We can say that access to finance is one of the most fundamental problems that require solutions for the future.”

War is hurting us

Evaluating the reflections of the Russia-Ukraine war on the Turkish shipbuilding industry, Kıran said: “First of all, this war hurts us a lot. We are deeply hurt by the moral troubles of this war between two friendly countries, rather than the financial troubles it brought to us. A significant part of the sheets we used in our shipyards was supplied from Ukraine. Especially with the cessation of the activities of the factories in Donekts, where the hottest conflicts of the war took place, and the closure of the Mariupol port, it became impossible for us to buy sheet metal from this country. This inevitably led our needy shipyards to other markets. Uncertainty and inconsistency in prices in this market, especially in China, cause great difficulties. Sheet metal costs have increased by at least 20-30% and raw material supply times have been extended considerably. On the other hand, it can be said that the only positive effect of this war on our market is the demand for our shipyards, especially for maintenance and repair, due to the inability of the shipyards in the Odessa Region to serve."